InkTek Printcare Nig Ltd #1 Oline Store

A4 Espson sublimation printer

Welcome to InkTek Nig Ltd

On Sale Products

₦ 13,000.00Original price was: ₦13,000.00. ₦ 12,500.00Current price is: ₦12,500.00.

₦ 14,000.00Original price was: ₦14,000.00. ₦ 13,500.00Current price is: ₦13,500.00.

₦ 4,000.00Original price was: ₦4,000.00. ₦ 3,500.00Current price is: ₦3,500.00.

₦ 11,500.00Original price was: ₦11,500.00. ₦ 9,000.00Current price is: ₦9,000.00.

₦ 350,000.00Original price was: ₦350,000.00. ₦ 335,000.00Current price is: ₦335,000.00.

₦ 6,000.00Original price was: ₦6,000.00. ₦ 4,000.00Current price is: ₦4,000.00.

₦ 180,000.00Original price was: ₦180,000.00. ₦ 175,000.00Current price is: ₦175,000.00.

₦ 190,000.00Original price was: ₦190,000.00. ₦ 180,000.00Current price is: ₦180,000.00.

₦ 15,000.00Original price was: ₦15,000.00. ₦ 10,000.00Current price is: ₦10,000.00.

₦ 250,000.00Original price was: ₦250,000.00. ₦ 240,000.00Current price is: ₦240,000.00.

₦ 380,000.00Original price was: ₦380,000.00. ₦ 370,000.00Current price is: ₦370,000.00.

₦ 950,000.00Original price was: ₦950,000.00. ₦ 930,000.00Current price is: ₦930,000.00.

₦ 3,000,000.00Original price was: ₦3,000,000.00. ₦ 2,900,000.00Current price is: ₦2,900,000.00.

OUR SUBLIMATION BLANKS

PRINTING PACKAGE FOR YOUR BUSINESS

Sublimation Priting Requirments

Epson A3/A4 printer

Set of sublimation inks

Sublimation Paper A4/A3

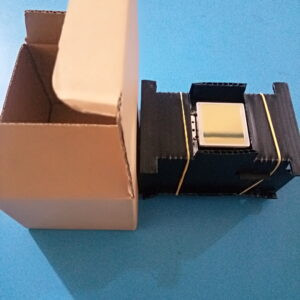

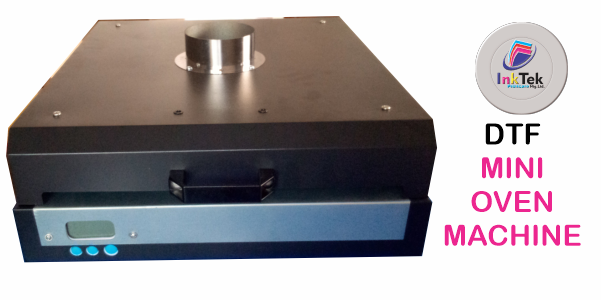

DTF Printing Requirements

Epson L805/L1800 printer

DTF Inks CY,MG,BK,WH,Y

DTF Powder/ AcroRip Software

ID Card Printing Requirements

Epson/Canon Printer

PVC Card/ID Card Tray

RC/ ID Card Template

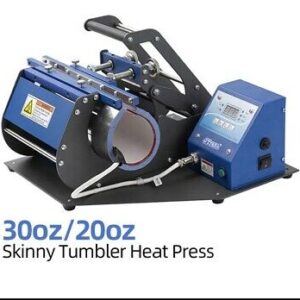

OUR HEAT TRANSFER PRODUCTS HOT SALE PRODUCTS WE HAVE VARIOUS KIND OF INK FOR YOUR PRINTER

ARE YOU HAVING ISSUE WITH YOUR MACHINE? CHECK WHAT WE HAVE FOR YOU ON OUR BLOG

REVIEW FROM OUR ESTEEM CUSTOMERS

[trustindex no-registration=google]

OUR HOT LINE +23407063636774 +23409133004777

Don’t Hesitate to Contact us for any Information.

Call us for immediate support to this number