Description

uncoated laser heat transfer paper for non coated mug

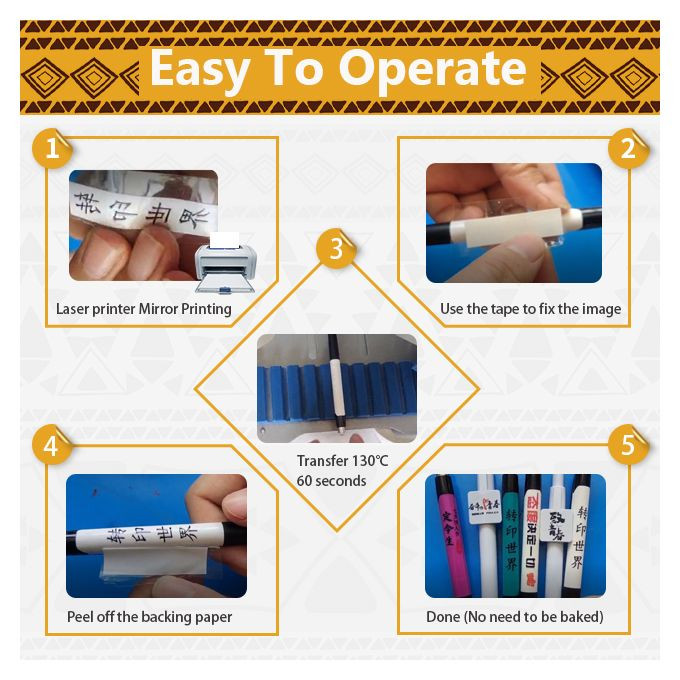

Step 1 :Printing

Printing Settings: Mirror Printing, Label, Paper Thickness/Heaviness: 120g-180g

Step 2: Cut your design

Use scissors to cut your design. Do NOT cut too close to the edge of the image, leaving a 2 ~ 3mm of margin.

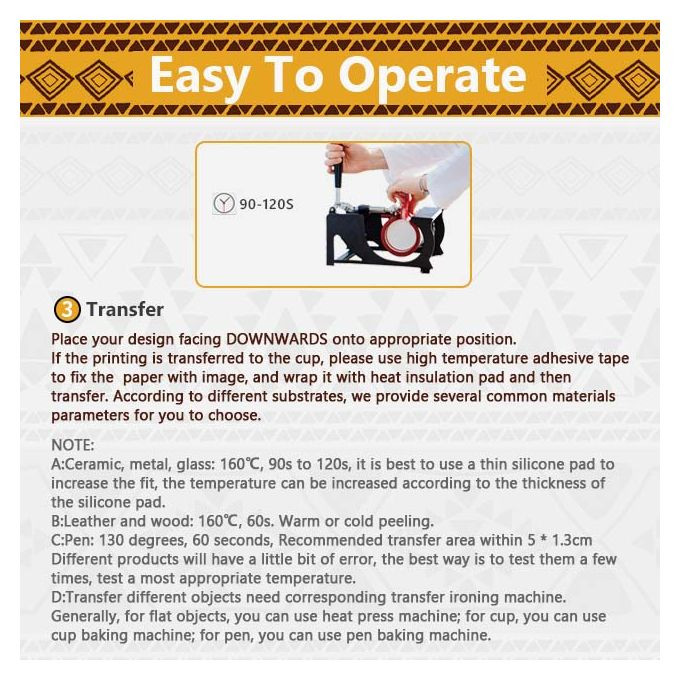

Step 3: Transfer

Place your design facing DOWNWARDS onto appropriate position.

If the printing is transferred to the cup, please use high temperature adhesive tape to fix the paper with image, and wrap it with heat insulation pad and then transfer. According to different substrates, we provide several common materials parameters for you to choose.

NOTE:

A:Ceramic, metal, glass: 160℃, 90s to 120s, it is best to use a thin silicone pad to increase the fit, the temperature can be increased according to the thickness of the silicone pad.

B:Leather and wood: 160℃, 60s. Warm or cold peeling.

C:Pen: 130 degrees, 60 seconds, Recommended transfer area within 5 * 1.3cm

Different products will have a little bit of error, the best way is to test them a few times, test a most appropriate temperature.

D:Transfer different objects need corresponding transfer ironing machine. Generally, for flat objects, you can use heat press machine; for cup, you can use cup baking machine; for pen, you can use pen baking machine.

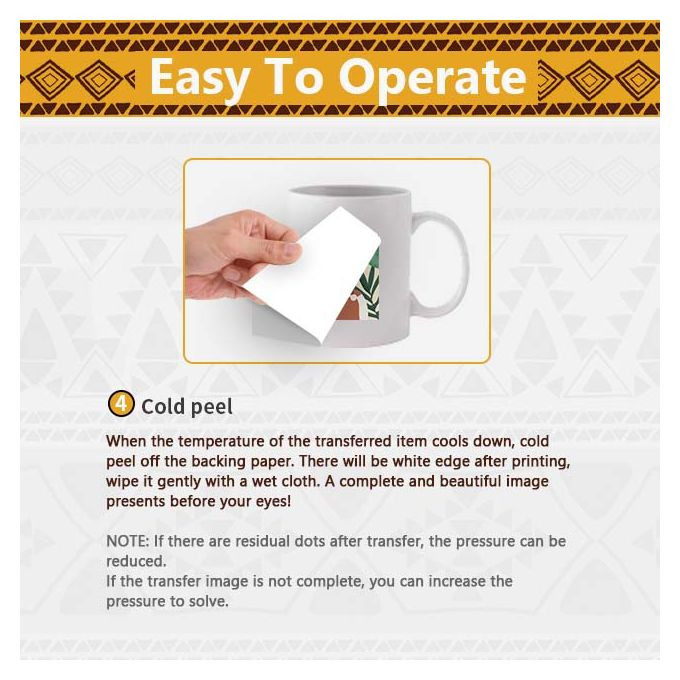

Step 4: Peel off the backing paper.

When the temperature of the transferred item cools down, cold peel off the backing paper. There will be white edge after printing, wipe it gently with a wet cloth. A complete and beautiful image presents before your eyes!

NOTE: If there are residual dots after transfer, the pressure can be reduced.

If the transfer image is not complete, you can increase the pressure to solve.

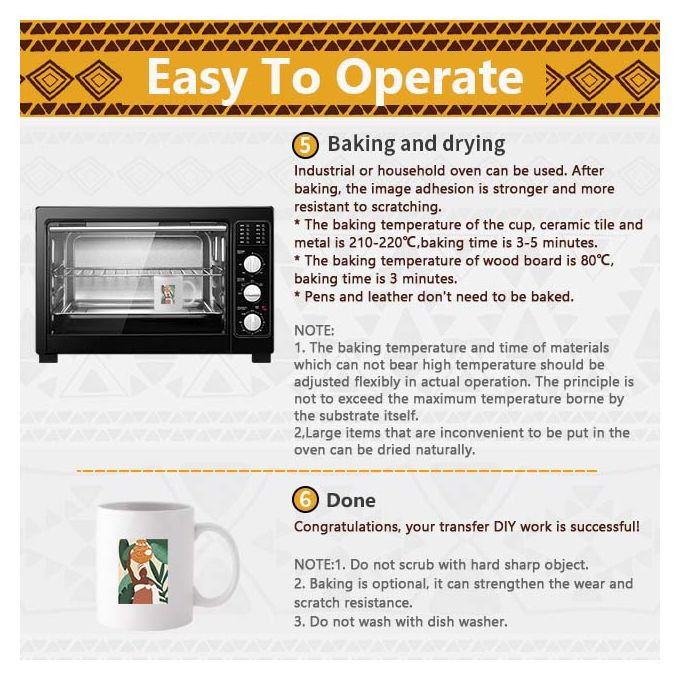

Step 5. Baking and drying

Industrial or household oven can be used. After baking, the image adhesion is stronger and more resistant to scratching.

* The baking temperature of the cup, ceramic tile and metal is 210-220℃,baking time is 3-5 minutes.

* The baking temperature of wood board is 80℃, baking time is 3 minutes

* Pens and leather don’t need to be baked.

NOTE:

1. The baking temperature and time of materials which can not bear high temperature should be adjusted flexibly in actual operation. The principle is not to exceed the maximum temperature borne by the substrate itself.

2,Large items that are inconvenient to be put in the oven can be dried naturally.

Step 6: DONE

Congratulations, your transfer DIY work is successful!

NOTE:1. Do not scrub with hard sharp object.

2. Baking is optional, it can strengthen the wear and scratch resistance.

3. Do not wash with dish washer.

Reviews

There are no reviews yet.